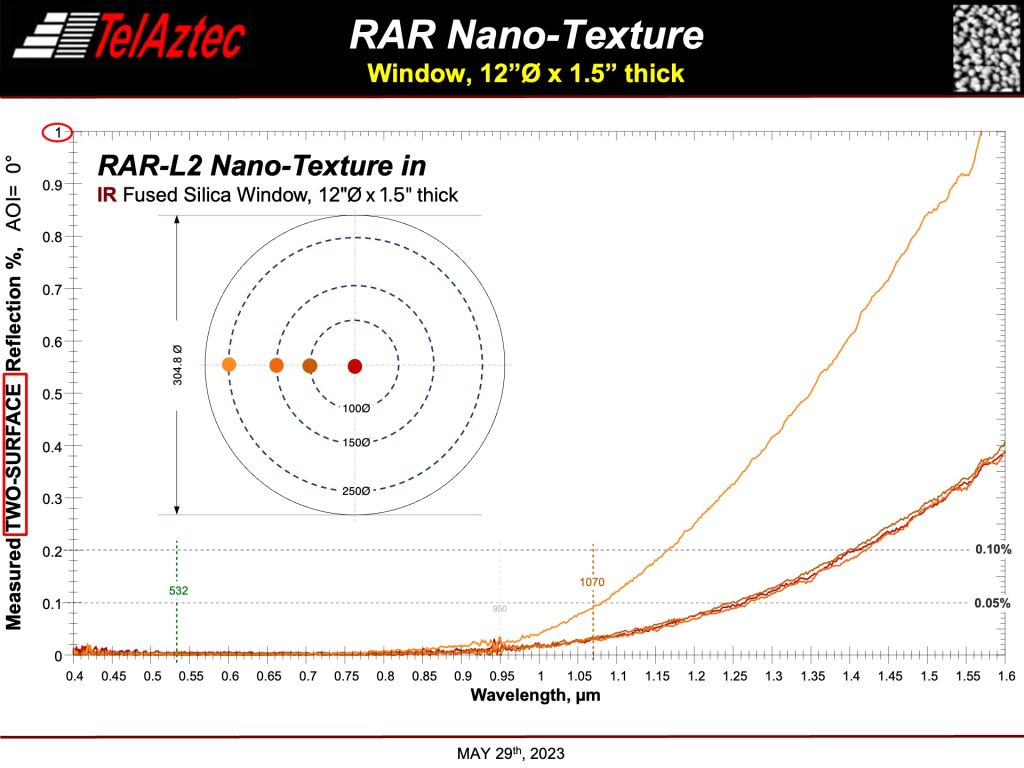

TelAztec’s novel plasma etching technology is capable of producing extremely low reflection levels from particularly demanding very large scale optics. RAR Nano-Texturing met the challenge of ultra-low reflection loss, zero-added surface absorption, and durability for the largest single commercial optic processed to date. The photo above shows Anthony Manni, CTO of TelAztec holding a massive, 12” diameter, 1.5” thick, RAR-L2 Nano-Textured fused silica window intended for a high power laser system. RAR performance and uniformity across the large window aperture is evident in the photo and in the measured total spectral reflection plot given below!

TelAztec has established a strong production track-record with over 50,000 RAR Nano-Textured optics delivered to commercial customers over the past 5 years. Customers commonly ask questions about size limitations for RAR Nano-Texturing a single substrate, and about the number of optics that can fit into a single RAR Nano-Texturing run.

TelAztec’s patented plasma etch process is defined by extremely short machine cycle times and excellent scalability; as a result the RAR Nano-Texturing process boasts production throughput and low costs equivalent or better than the largest commercial thin-film AR coating providers! Operating multiple 20cm and 30cm etch tools, TelAztec has demonstrated the ability to support high-volume production with excellent batch-to-batch repeatability and intra-batch uniformity.